Best compressed air leak detector is the Fluke ii900 Sonic Industrial Imager. This device quickly identifies leaks.

If you need a reliable compressed air leak detector, look no further than the Fluke ii900 Sonic Industrial Imager. By pinpointing leaks efficiently, this tool helps you save time and money on repairs. Its advanced technology and user-friendly design make it a top choice for industries that rely on compressed air systems.

With the Fluke ii900, you can detect leaks with precision and address them promptly to maintain optimal performance. Say goodbye to costly air leaks and hello to increased efficiency with this cutting-edge leak detector.

Types Of Compressed Air Leak Detectors

Discover the top-tier options for compressed air leak detectors, ensuring optimal air system efficiency. With advanced technology, innovative designs, and reliable performance, these detectors identify leaks swiftly, allowing prompt repairs to reduce energy waste and operational costs. Opt for the best detector for enhanced productivity.

| Types of Compressed Air Leak Detectors | |

|---|---|

| Ultrasonic Leak Detectors | Electronic Leak Detectors |

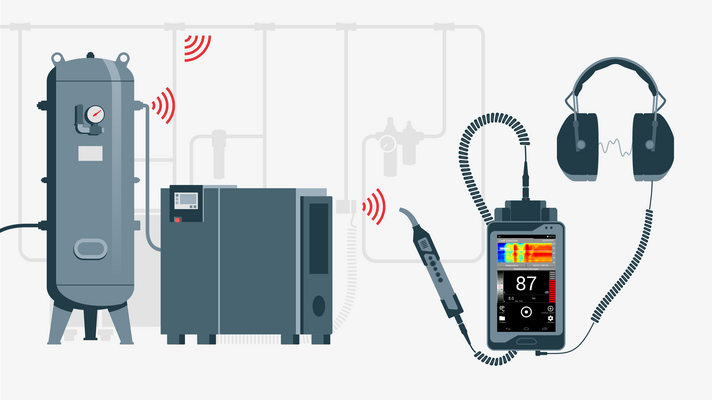

Compressed air leak detectors come in different types like ultrasonic and electronic detectors. Ultrasonic detectors work by detecting high-frequency sound waves produced by air leaks. Electronic detectors use sensors to identify changes in electric currents caused by leaks. Both types are efficient in pinpointing compressed air leaks in industrial settings. Regular use of these detectors can help prevent energy and production losses by identifying and fixing leaks promptly. Companies that utilize compressed air systems can benefit from investing in high-quality leak detectors to maintain optimal efficiency and reduce operational costs in the long run.

Credit: www.fluke.com

Top Features To Look For In A Compressed Air Leak Detector

When selecting the best-compressed air leak detector, there are a few important features to consider. Firstly, sensitivity and accuracy are crucial. You want a detector that can effectively identify even the tiniest leaks with utmost precision. The ability to detect leaks accurately will save you time and money in the long run.

Secondly, portability and ease of use are essential factors. A lightweight and compact leak detector will allow you to easily navigate through tight spaces and reach inaccessible areas. Additionally, an intuitive interface and simple operation will enable quick and hassle-free leak detection.

Finally, consider the multifunctionality of the detector. Look for features such as the ability to measure air velocity, temperature, and humidity, as these additional functions can provide valuable insights and help you identify potential issues beyond mere leaks.

| Sensitivity and Accuracy | Portability and Ease of Use | Multifunctionality |

|---|---|---|

| Effectively identify even tiny leaks | Lightweight and compact design | Measure air velocity, temperature, and humidity |

| Precise detection saves time and money | Easily navigate tight spaces | Gain valuable insights beyond leaks |

| Intuitive interface and simple operation |

Top Solutions For Air Leak Detection

Brand X Compressed Air Leak Detector: This solution offers advanced technology for precise air leak detection in industrial settings. With its user-friendly interface, it provides real-time data on air leaks, helping businesses save on energy costs and optimize their operations.

Brand Y Advanced Air Leak Detection System: This cutting-edge system utilizes innovative sensors to accurately identify and locate air leaks within pneumatic systems. Its customizable features make it a versatile solution for various industrial applications, ensuring efficient leak detection and maintenance.

Case Studies: Successful Implementation Of Air Leak Detection Systems

Implementing compressed air leak detectors in manufacturing plants has yielded significant benefits. Manufacturing Plant A saw a notable increase in efficiency after identifying and fixing air leaks. This resulted in reduced energy consumption and cost savings. Similarly, Warehouse B experienced substantial cost savings by promptly repairing detected leaks. The timely detection and resolution of air leaks led to improved operational efficiency and a reduction in energy expenses. These case studies highlight the tangible advantages of utilizing air leak detection systems in industrial settings. By effectively addressing compressed air leaks, businesses can enhance their sustainability efforts and achieve operational cost savings.

Tips For Effective Air Leak Detection

Regular inspections and maintenance of your compressed air system are important for effective air leak detection. By conducting regular inspections, you can identify and fix air leaks before they become major issues. This will not only save you money on energy costs but also prolong the lifespan of your equipment.

In addition to inspections, training your employees on proper leak detection techniques is crucial. By educating your workforce, they will be able to identify and report any potential air leaks early on. This will help prevent wasted energy and ensure a safe working environment.

Remember, the key to effective air leak detection is staying proactive. By implementing regular inspections, maintenance, and employee training, you can keep your compressed air system running efficiently and minimize energy wastage.

Credit: www.sonotec.eu

Cost-benefit Analysis Of Using Compressed Air Leak Detectors

Maximize efficiency and reduce costs with the best-compressed air leak detector. Conducting a cost-benefit analysis on using compressed air leak detectors can help identify and address leaks, leading to significant savings and improved operational performance. With its advanced technology, the best-compressed air leak detector ensures accurate and efficient detection, making it an essential tool for businesses aiming to enhance their compressed air systems.

| When evaluating the cost-benefit of using compressed air leak detectors | initial investment must be weighed against the potential for long-term savings. |

| By detecting and fixing leaks promptly, companies can significantly reduce operational costs. | Preventing air leaks also has a positive impact on the environment by lowering energy consumption. |

Credit: www.pctflow.com

Frequently Asked Questions For Best Compressed Air Leak Detector

What Is A Compressed Air Leak Detector?

A compressed air leak detector is a tool used to identify and localize leaks in compressed air systems. It helps maintain efficiency, save energy, and reduce operational costs by preventing air leakages.

How Does A Compressed Air Leak Detector Work?

A compressed air leak detector works by producing ultrasonic sounds that are inaudible to humans but can be detected by the tool. When it detects a leak, it translates the ultrasonic signals into audible sounds or visual indicators for the user to locate and fix the problem.

Why Is It Important To Detect Compressed Air Leaks?

Detecting compressed air leaks is crucial as it helps conserve energy, reduce operational costs, and prolong the lifespan of equipment. By fixing leaks promptly, businesses can enhance their operational efficiency and minimize environmental impact.

What Are The Benefits Of Using A Compressed Air Leak Detector?

Using a compressed air leak detector can lead to significant cost savings, increased productivity, and improved sustainability. It allows businesses to identify and repair leaks swiftly, contributing to a more efficient and environmentally friendly compressed air system.

Conclusion

To sum it up, finding the best-compressed air leak detector is crucial for maintaining the efficiency and safety of your industrial processes. With the right detector, you can quickly identify and fix leaks, saving valuable energy and resources. Whether you choose a handheld device or a stationary one, invest in a reliable detector that is accurate, easy to use, and offers advanced features like data logging.

By choosing the right detector, you can ensure the smooth operation of your compressed air system and ultimately enhance your productivity.